The manufacturing industry is moving beyond digitalization, adopting a new perspective on quality, sustainability, and operational excellence. At our PitStop event, the preferences gathered from 162 corporate professionals representing 92 different manufacturing companies revealed that the sector is not only focused on new technologies, but is also in a continuous search for improvement and integration within existing systems.

Let’s take a closer look at the data and key dynamics driving this transformation.

-- Research Methodology: An Objective Data Collection Process --

As part of our PitStop event series, we conducted a comprehensive analysis of technology preferences among 162 corporate professionals from 92 different manufacturing organizations. To ensure unbiased results, we employed an objective presentation method and collected independent evaluations from all participants.

Priorities Shaping the Future of Manufacturing

With a data-driven approach to manufacturing, companies are now focused on continuously monitoring and ensuring quality, making sustainability measurable, and managing all operations transparently from the shop floor to the central office. This holistic perspective not only meets customer and regulatory expectations but also makes business processes more agile and efficient. From the production line to the field team, higher standards of traceability and sustainability are emerging at every step.

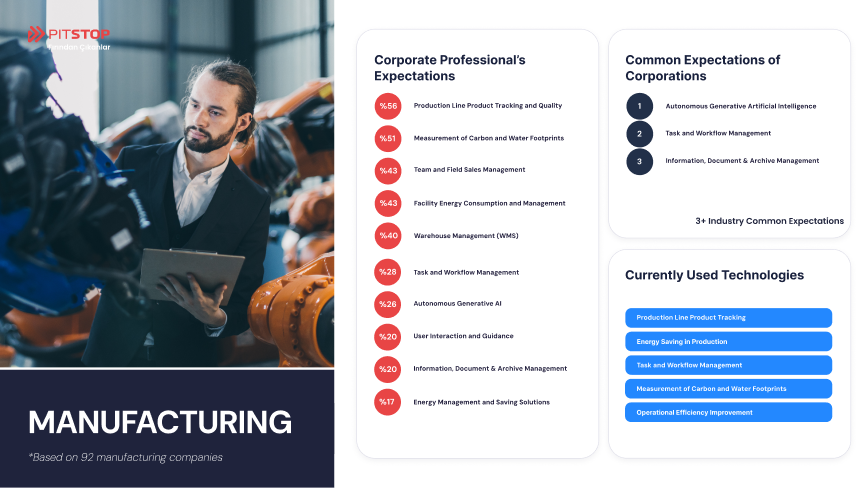

Key Expectations of Organizations

- 56% – Production Line Product Tracking and Quality

- 51% – Measurement of Carbon and Water Footprints

- 43% – Team and Field Sales Management

- 43% – Facility Energy Consumption and Management

- 40% – Warehouse Management (WMS)

- 28% – Task and Workflow Management

- 26% – Autonomous Generative AI

- 20% – User Interaction and Guidance

- 20% – Information, Document & Archive Management

- 17% – Energy Management and Saving Solutions

As the connections among these priorities strengthen, quality, sustainability, and team management create a new synergy in manufacturing. The real opportunity lies in recognizing this holistic picture—focusing not only on individual areas but on all interconnected transformation points, and growing investments in an integrated way.

Current Digital Practices: Decoding the Window of Opportunity

The concentration of today’s widely adopted digital applications in manufacturing around a few key areas shows that companies, on their transformation journey, are prioritizing “safe” and tangible value-generating domains. However, when compared to future expectations, it’s clear that current implementations are still mainly focused on operational efficiency and basic traceability. This indicates that the sector is still pursuing a risk-averse, controlled, and incremental digitalization strategy. To achieve sustainable competitive advantage and genuine transformation, more integrated and innovative steps are needed.

Current practices suggest that companies have yet to unlock their full digital potential, with significant opportunity remaining in data integration, advanced analytics, and holistic management for the next leap forward.

- Production Line Product Tracking

- Energy Saving in Production

- Task and Workflow Management

- Measurement of Carbon and Water Footprints

- Operational Efficiency Improvement

Task and Workflow Management: The Foundation of Digitalization and a Catalyst for Transformation

Task and workflow management solutions have already been implemented by a significant portion of manufacturing companies. However, their relatively low ranking on professionals’ priority lists indicates that this area is often perceived as a “foundational investment” rather than as a true driver of strategic growth or productivity. In reality, companies that elevate their business processes through smart platforms—enabling data-driven decision-making, cross-functional integration, and real-time management—are poised to stand out in the future. In short, moving beyond basic task management and leveraging this area as a strategic lever for transformation is likely to define the next arena of competition in the sector.

Strategic Roadmap: Shaping the Future Together

A close look at current practices and priorities in the manufacturing sector reveals a path of digitalization that is still cautious, incremental, and risk-averse. Yet, to stand out in today’s—and especially tomorrow’s—competitive landscape, meeting only basic needs is not enough; radical integration in areas like data connectivity, sustainability, and end-to-end process management is essential.

The greatest opportunity lies in moving beyond siloed digitalization investments to build transparent, agile systems where quality, sustainability, team management, and energy efficiency are seamlessly integrated. Now is the time to develop strategies not around isolated initiatives, but through transformation points that feed and amplify each other across the entire operation.

The steps taken today will determine who will be followers and who will become pioneers in tomorrow’s manufacturing world. It’s time to strategically bring together all these interconnected transformation points for true impact.

Discussion